|

Copper is widely used to make electrical wiring and in other applications that utilize its high electrical conductivity. Crude copper, which is usually obtained by pyrometallurgical methods, is not suitable to serve in electrical applications because impurities greatly reduce the metal's conductivity. A purity > 99.7% is therefore required these applications. Purification of copper is achieved by electrorefining. Large slabs of crude copper serve as the anodes in the cell, and thin sheets of pure copper serve as the cathodes.

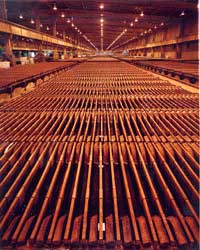

The Amarillo refinery houses 2,400 tanks in a single building

The electrolyte consists of an acidic solution of CuSO4. Application of a suitable voltage to the electrodes causes oxidation of copper metal at the anode and reduction of Cu2+ to form copper metal at the cathode. This strategy can be used because copper is both oxidized and reduced more readily than water.

Electrolysis cell for refining of copper. As the anodes dissolve away, the cathodes on which the pure metal is deposited grow in size.

The impurities in the copper anode include lead, zinc, nickel, arsenic, selenium, tellurium, and several precious metals including gold and silver. Metallic impurities that are more active than copper are readily oxidized at the anode but do not plate out at the cathode because their reduction potentials are more negative than that for Cu2+. However, less active metals are not oxidized at the anode. Instead, they collect below the anode as a sludge that is collected and processed to recover the valuable metals. The anode sludges from copper-refining cells provide one fourth of U.S. silver production and about one eighth of U.S. gold production.