Crevice Corrosion |

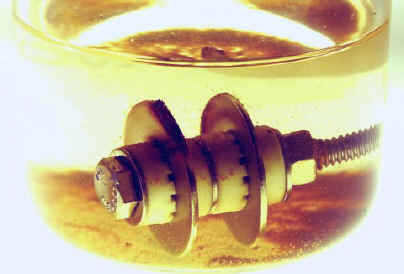

A good example of how crevice corrosion can be reproduced and accelerated in a laboratory environment is the formation of occluded cells with multiple crevice assemblies (MCAs), as described in the ASTM G78 Standard Guide for Crevice Corrosion Testing of Iron-Base and Nickel-Base Stainless Alloys in Seawater and Other Chloride-Containing Aqueous Environments.

In this test, washers make a number of contact sites on either side of the specimens. The number of sites showing attack in a given time can be related to the resistance of a material to initiation of localized corrosion, and the average or maximum depth of attack can be related to the rate of propagation. The large number of sites in duplicate or triplicate specimens is amenable to probabilistic evaluation.

The susceptibility to localized corrosion becomes quite visible once a specimen equipped with these Teflon washers has been exposed to a corrosive environment for an extended period of time. 'Click here' to see a S30400 specimen having spent 30 days in a solution containing 0.5 M FeCl3 and 0.05 M NaCl.

|

ASTM G78-01 Standard Guide for Crevice Corrosion Testing of Iron-Base and Nickel-Base Stainless Alloys in Seawater and Other Chloride-Containing Aqueous Environments

This guide provides information for conducting crevice-corrosion tests and identifies factors that may affect results and influence conclusions. The procedures described in the guide can be used to identify conditions most likely to result in crevice corrosion and provide a basis for assessing the relative resistance of various alloys to crevice corrosion under certain specified conditions.