|

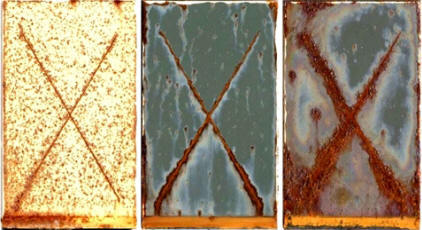

Lateral undercutting corrosion at a scratch in the paint, or at a sheared edge (where the paint/primer/metallic coating/steel are all exposed to potential corrosion).

| Undercutting corrosion of a scribed surface during testing is an indication of poor paint performance. The net effect of this lateral undercutting corrosion is the loss of adhesion between the paint and the metal substrate. This particular type of corrosion can be quite damaging since it combines all the elements of a crevice corrosion scenario, i.e. small local anode/large external anode, formation of an acidic environment, production of gaseous hydrogen. |

|

The corrosion can occur by (a) chemical reaction along the paint/ metallic coating interface which can cause the chemical adhesion bond to be degraded, or (b) bulk corrosion of the metallic coating leaving the paint totally “unconnected” to the steel sheet.

|

To minimize the tendency for loss of paint adhesion through undercutting corrosion or blistering, one needs to take into account very specific recommendations from the steel supplier and paint manufacturers. The “best” coated-product design requires that the user pay attention to the type and thickness of the metallic coating, the type of pretreatment, the type and thickness of the primer, and the type and thickness of the topcoat. |