|

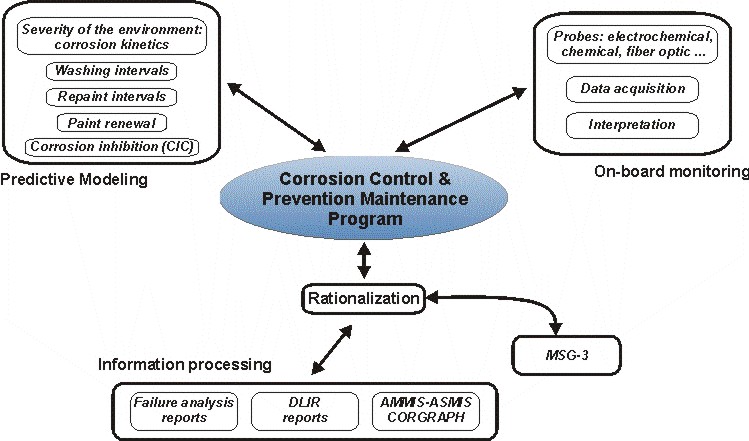

The creation of a link between environmental corrosivity and certain maintenance and inspection schedules was a major recommendation of a 1991 study commissioned to examine the practicality of developing a corrosion modeling program in the Canadian Forces [1]. Similar recommendations have been made elsewhere [2]. Such linkages were previously explored for the USAF in the form of simple practical algorithms [3], related to aircraft washing schedules for example. A study is underway at RMC to characterize the environmental corrosivity prevailing at CF Bases across Canada. The significant time-dependence of the corrosivity on a seasonal scale is an important finding of this study to date.

Many corrosion prone areas of CF aircraft are difficult and hence costly to inspect. These inaccessible areas presently require periodic inspection, regardless of whether corrosion damage has taken place or not. Significant maintenance and inspection efforts and costs could be saved, if the severity of corrosion could be determined (independently), by on-board corrosion surveillance sensors. The aircraft instrumented with the sensors would essentially represent a smart structure, which would diagnose where and when attention should be directed at corrosion problems.

Various aircraft corrosion sensing systems are under development, including thin film electrochemical sensors and fiber optic probes. Some of these sensors have been installed on board aircraft for evaluation purposes in several countries. In the CF, an on-board Corrosion Diagnostic System was installed in 1994 on a CP-140 Aurora on a trial basis.

References