Module Six of CCE 281 Corrosion: Impact, Principles, and Practical Solutions

Corrosion Fatigue |

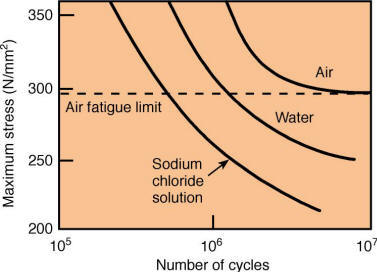

Corrosion-fatigue is the result of the combined action of an alternating or cycling stresses and a corrosive environment. The fatigue process is thought to cause rupture of the protective passive film, upon which corrosion is accelerated.If the metal is simultaneously exposed to a corrosive environment, the failure can take place at even lower loads and after shorter time.

|

In a corrosive environment the stress level at which it could be assumed

a material has infinite life is lowered or removed completely. Contrary

to a pure mechanical fatigue, there is no fatigue limit load in corrosion-assisted

fatigue.

Corrosion fatigue and fretting are both in this class. Much lower failure stresses and much shorter failure times can occur in a corrosive environment compared to the situation where the alternating stress is in a non-corrosive environment.(reference) |

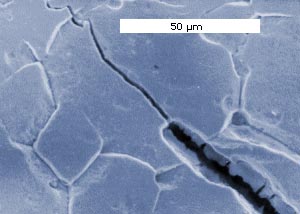

| The fatigue fracture is brittle and the cracks are most often transgranular, as in stress-corrosion cracking, but not branched. The picture shown here reveals a primary corrosion-fatigue crack that in part has been widened by a secondary corrosion reaction. The corrosive environment can cause a faster crack growth and/or crack growth at a lower tension level than in dry air. Even relatively mild corrosive atmospheres can reduce the fatigue strength of aluminum structures considerably, down to 75 to 25% of the fatigue strength in dry air. (photo courtesy) |

|

No metal is immune from some reduction of its resistance to cyclic stressing if the metal is in a corrosive environment. Control of corrosion fatigue can be accomplished by either lowering the cyclic stresses or by various corrosion control measures (see checklist).

| (previous) | Page 22 of 23 | (next) |

- Corrosion incidents of aircraft and helicopters

- Structural integrity

- Pitting corrosion incidents

- PCF models

- Validity of PCF models

Protection Possibilities Checklist

- Minimize or eliminate cyclic stresses

- Reduce stress concentration or redistribute stress (balance strength and stress throughout the component)

- Select the correct shape of critical sections

- Provide against rapid changes of loading, temperature or pressure

- Avoid internal stress

- Avoid fluttering and vibration-producing or vibration-transmitting design

- Increase natural frequency for reduction of resonance corrosion fatigue

- Limit corrosion factor in the corrosion-fatigue process (more resistant material / less corrosive environment).