|

|

|

|

|

|

|

|

|

|

|

|

Galvanic Test or Crevice Test?

This page describes a very expedient combination test designed to reveal the GOOD, the BAD, and the UGLY in the commercially available corrosion prevention compounds listed below. All these products are advertised as THE BEST IN THE WORLD, meaning that the competitors are simply not performing or possibly even aggravators. Additionally there are no standard test to reveal the main properties these products, i.e. their corrosion protection efficiency. There are all kinds of tests to qualify these products for the market: environmental, safety, creep rate, viscosity, dielectric strength ... but none for the main reason they should be used in the first place, THEIR CORROSION PROTECTION PERFORMANCE.

See the results after 120 hours (only 5 days!): the front and the back

In the face of this complete vacuum, the Corrosion Doctors have rolled their sleeves, scratched their head and come up with a test you can easily do in your basement for a limited number of trips to the local hardware store.

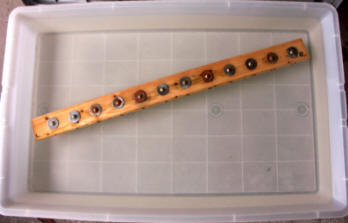

| First, the torture bench. Nothing complicated, but my GOD, so powerful: simple tap water and a porous medium. The piece wood you see floating here has already had been drilled to receive twelve sacrificial lambs that will be offered to the corrosion Devil so he will not come to haunt us and lure us to the scrap yards of the world. |

|

| And then we add a little bit of salt that will really really make a big difference. Adding salt to the wet wood now makes it an extremely powerful corrodent for many metals and particularly for steel and aluminum. After a few hours, the salt crystals had disappeared into the wet wood waiting for their prey to arrive. Salt is not rare and is a realistic aggravator. Salt is used on many icy winter roads of North America as a deicing agent. Salt is also an important component of seawater. |

| A steel-brass galvanic couple (brass bolt and steel washer + bolt) was used in this simple experiment to test the efficiency of a series of corrosion prevention compounds. As the galvanic series indicates brass is basically equivalent to copper in nobility and steel corrosion should be accelerated by the presence of both metals. It is therefore a realistic arrangement common in cars, aircraft, or ships where these products are widely used. The corrosion prevention compounds to be tested can be put on the top steel washer and on the bottom nut. There is a choice here. We will, for the moment, let your imagination decide what we did in the present test. Just a hint: we wanted to test the corrosion efficiency as well as the penetrating efficiency of the corrosion preventive compounds. |

|

| Here is how it looks after having assembled pretreated washers, bolts and nuts unto the presoaked wooden board. As you can see we have numbered each of the sample site for future reference. In this particular test, we have tried nine commercial CPCs, two bare steel washers and one galvanized . The picture you see here was taken after two days of testing. Can you already see some serious differences between some of the test coupons? |

| Oh, we forgot to mention another corrosion aggravating factor we introduced in the test. Alternate wetting and drying is a serious factor in many natural corrosion situations. So why not sprinkle our poor CPC prep washers with squirts of a 3% sodium chloride solution. |

|

The corrosion race is on! May the BEST win!

Simple experiments to illustrate the theory:

Corrosion current, Galvanic coupling, Rust preventive testing

List of washers and CPCs used in this study:

One galvanized washer

Two bare steel washers

One washer pre-coated with WD-40

One washer pre-coated with Rust Cure 3000

One washer pre-coated with Krown T-40

One washer pre-coated with Boeshield T-9

One washer pre-coated with Rust Check Red

One washer pre-coated with Rust Check Dripless

One washer pre-coated with ACF-50

One washer pre-coated with Corrosion Block

One washer pre-coated with LPS-2

The two million dollars question is: which of these products would you like to spray or have sprayed on your precious vehicle?

Something is missing! Please send your suggestion to our