|

On an FPSO, tanks can be in a variety of different services

including, seawater ballast, void, produced water storage and wet and dry oil

storage. As with other parts of the system, the issue is again the longer life

requirement, and the difficulty of entering the tanks for inspection and

maintenance with the vessel operational. The use of dehumidification systems is

growing for protection of void tanks, for the remainder coatings and cathodic

protection are the norm.

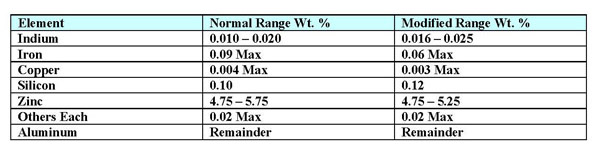

Our company was recently engaged in the offshore retrofit of an FPSO tank that was in produced water service; temperatures were around 70oC. The tank coating system was fairly badly degraded and the anodes in the tanks were heavily depleted. There is some concern using Aluminum anodes in certain areas of tanks due to the risk of sparking if the anodes fall off, zinc is preferred. In this case the only choice was aluminum, the zinc anodes would have probably passivated in these tank fluids. Indeed the aluminum anodes had to be carefully alloyed as indicated in the Table below to optimize their galvanic capacity that tends to fall off rapidly with increased service temperature above about 60oC.

Chemical Composition Modification of Al-Zn-In

Sacrificial Anodes for Produced Water Service

The anodes were deployed on rack type structures, as shown

below, that were assembled inside the tank and attached with mechanical

connections; this was necessary due to the limited access and the inability to

perform hot work with the vessel in service. In addition two permanent reference

electrodes were installed to facilitate ease of monitoring of the system.

Retrofit Anode Racks inside a FPSO

Produced Water Tank

Whenever a retrofit is planned inside a tank with a

degraded coating, it is important to consider the rate of hydrogen build-up in

the tank from the corroding anodes. This is a particular risk for tanks that

have a small ratio of void space to filled space, tanks that are often filled

and emptied and tanks with limited or restricted venting. Before embarking on

such a project calculate the volume of hydrogen that will be discharged during

the worst case, i.e. when tank is being quickly refilled after having been

empty. If the potential hydrogen concentration approaches the lower explosive

limit, the use of soft coatings should be investigated, this will reduce current

demand and hence the volume of hydrogen produced. This was not a problem on the

aforementioned tanks, which never exceeded 75% of fill.

The use of permanent reference electrodes makes a lot of

sense. In ballast tanks, the most reliable electrode is a zinc sw. electrode. A

low cost field installable electrode system has been developed for this purpose.

Electrodes can be easily routed in the tanks and may be built to length

offshore. Routing through a deck penetration allows the tanks to be monitored

with no hatch removal or tank entry required.

See also: Fouling,FPSO, Ions in seawater,DO in seawater, Seawater scaling, Anti-fouling coatings

|