|

Welcome

Site index

A to Z listing

Advertising

Books

Corrosion glossary

Disclaimer

Famous scientists

Corrosion course

Distance Ed

Doomsday scenarios

Links

Modules

Monitoring glossary

Photo gallery

Rare earths

Search this site

Textbook assignments

Toxic elements

Water glossary

Webmaster

| |

Bhopal Accident

Bhopal is probably the site of the greatest

industrial disaster in history.

Between 1977 and 1984, Union Carbide India Limited (UCIL),

located within a crowded working class neighborhood in Bhopal, was licensed by

the Madhya Pradesh Government to manufacture phosgene, monomethylamine (MMA),

methylisocyanate (MIC) and the pesticide carbaryl, also known as Sevin.

| On the night of the 2-3 December 1984 water inadvertently

entered the MIC storage tank, where over 40 metric tons of MIC were being

stored. The addition of water to the tank caused a runaway chemical

reaction, resulting in a rapid rise in pressure and temperature. The heat

generated by the reaction, the presence of higher than normal concentrations

of chloroform, and the presence of an iron catalyst , produced by the corrosion of the stainless steel tank

wall,

resulted in a reaction of such momentum, that gases formed could not be

contained by safety systems. As a result, MIC and other reaction products, in

liquid and vapor form, escaped from the plant into the surrounding areas.

There was no warning for people surrounding the plant as the emergency

sirens had been switched off. The effect on the people living in the shanty

settlements just over the fence was immediate and devastating. Many died in

their beds, others staggered from their homes, blinded and choking, to die

in the street. |

(graphic

courtesy) |

Many more died later after reaching hospitals and emergency aid

centers. The early acute effects were vomiting and burning sensations in the

eyes, nose and throat, and most deaths have been attributed to respiratory

failure. For some, the toxic gas caused such massive internal secretions that

their lungs became clogged with fluids, while for others, spasmodic constriction

of the bronchial tubes led to suffocation. It is been estimated that at least

3000 people died as a result of this accident, while figures for the number of

people injured currently range from 200,000 to 600,000, with an estimated

500,000 typically quoted. The factory was closed down after the accident.

|

|

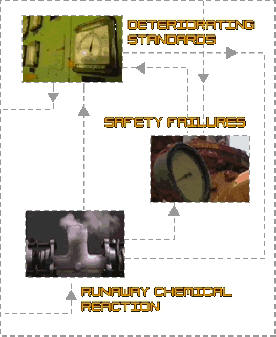

The Bhopal disaster was the result of a

combination of legal, technological, organizational, and human

errors. The immediate cause of the chemical reaction was the seepage

of water (500 liters) into the MIC storage tank. The results of this

reaction were exacerbated by the failure of containment and safety

measures and by a complete absence of community information and

emergency procedures. (photo

courtesy) |

The long term effects were made worse by the absence of systems

to care for and compensate the victims. Furthermore, safety standards and

maintenance procedures at the plant had been deteriorating and ignored for

months. A listing of the defects of the

MIC unit runs as follows(reference):

-

Gauges measuring temperature and pressure in the

various parts of the unit, including the crucial MIC storage tanks,

were so notoriously unreliable that workers ignored early signs of

trouble.

-

The refrigeration unit for keeping MIC at low

temperatures (and therefore less likely to undergo overheating and

expansion should a contaminant enter the tank) had been shut off for

some time.

-

The gas scrubber, designed to neutralize any escaping

MIC, had been shut off for maintenance. Even had it been operative,

post-disaster inquiries revealed, the maximum pressure it could handle

was only one-quarter that which was actually reached in the accident.

-

The flare tower, designed to burn off MIC escaping

from the scrubber, was also turned off, waiting for replacement of a

corroded piece of pipe. The tower, however, was inadequately designed

for its task, as it was capable of handling only a quarter of the

volume of gas released.

-

The water curtain, designed to neutralize any

remaining gas, was too short to reach the top of the flare tower, from

where the MIC was billowing

-

The lack of effective warning systems; the alarm on

the storage tank failed to signal the increase in temperature on the

night of the disaster

-

MIC storage tank number 610 was filled beyond

recommended capacity; and -a storage tank which was supposed to be

held in reserve for excess MIC already contained the MIC.

Other corrosion accidents:

Aloha,

Bhopal,

Carlsbad,

Davis-Besse,

Guadalajara, EL AL,

Erika,

F-16,

FAC,

Flixborough,

Gaylord Chemical,

Oil pipeline

releases, Pitting of aircraft and helicopters,

Prudhoe Bay,

Silver bridge,

Swimming

Pool

|