|

Organized studies have been devoted to corrosion for a longer time than most people realize. The British Association for the Advancement of Science appropriated a sum of money for a series of corrosion experiments on the corrosion of cast and wrought iron in the 1830ís. Experiments were conducted by Robert Mallet and reported by him in 1838, 1840, and 1843. Mallet's work was done in an era in which gifted scientists were investigating the properties of matter.

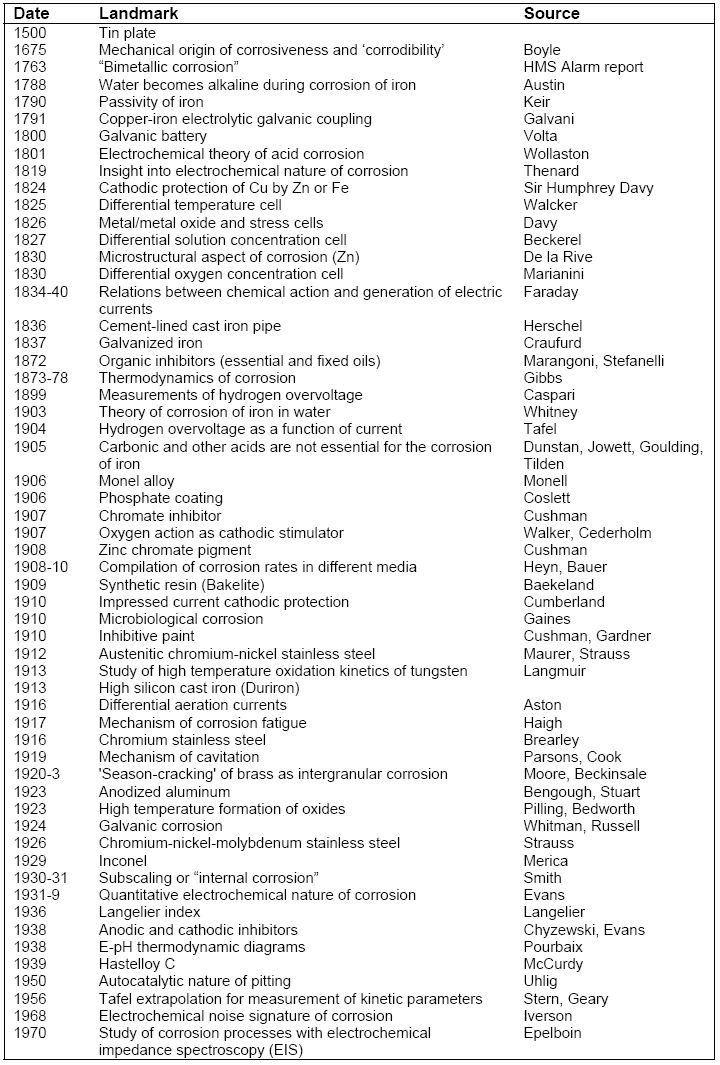

Many interesting references and reflections on historical aspects of corrosion can be found in the special Symposium that was held to celebrate NACE International fiftieth anniversary [9]. The following Table presents some historical landmarks of discoveries related to the understanding and management of corrosion.

Historical landmarks of discoveries related to the understanding and management of corrosion

The science of corrosion has had two periods of rapid advancement. One, in the first half of the nineteenth century, was a result of intense and sustained scientific interest and activity aroused by the invention of the galvanic battery, and the controversy over the nature and source of the galvanic current. The other, in the first half of the twentieth century, was stimulated by growing realization of the immense economic cost of corrosion in a rapidly developing industrial age. In the latter period, a number of theories and facts established in the earlier one were rediscovered or elaborated, or both. These include the electrochemical theory of corrosion, proposed by Wollaston in 1801, developed by de La Rive in 1830, confirmed by Ericson-Auren and Palmaer in 1901, and rediscovered by Whitney in 1903 [10].

As early as 1819, Hall demonstrated the necessity of dissolved oxygen for appreciable corrosion of iron in water at ordinary temperatures and Sir Humphrey Davy published results of his work on cathodic protection of copper bottoms for British naval vessels in 1824. These early experiments established a practical base for the application of cathodic protection which led to the development of galvanized iron.

In 1906, Committee U of the American Society for Testing Materials (ASTM) was formed to promote the development of corrosion tests. Shortly afterward, other organizations began to pay attention to corrosion and its control.

Among pioneers in studying the effects of corrosion was the American Committee on Electrolysis, which noted in 1921 that its preliminary report had been published in October, 1916. This committee, composed of representatives of the American Institute of Electrical Engineers, American Electric Railway Association, American Railway Engineering Association, National Bureau of Standards, and others, concerned itself with the then serious problem of stray current damage to underground metal structures, especially the protection of communication cable from electrified street and interurban railways .

An "Electrolysis Surveyor" using a McCollum Earth Current Meter from the early 1920s. (Courtesy of East Bay Municipal Utility District)

"Pits in 16 inch Sheet Iron Water Main in San Francisco's East Bay that failed in one month due to leakage of current from electric streetcars. (Photo dated August 10, 1926, Courtesy of East Bay Municipal Utility District).

In England, the Corrosion Committee of the Iron and Steel Institute issued its first report in 1931 and its sixth in 1959. An American Coordinating Committee on Corrosion was organized with representatives from 17 technical societies in 1938. This group, which aimed at coordinating the activities of societies to prevent duplicated work was absorbed by the National Association of Corrosion Engineers (NACE) in 1948 and was renamed the Inter-Society Committee on Corrosion Control. It functioned in a semi-autonomous manner until it was finally disbanded about ten years later. This was largely because the growth of abstract publications and numerous other periodicals permitted easy interchange of most information.

Although Germany had a corrosion journal (Korrosion and Metallschutz) prior to World War II, which was interrupted during the war and reissued after its end under a new title (Werkstoffe und Korrosion), it was not until after NACE began publishing the magazine Corrosion in 1945 that journals on corrosion control were started in other countries. Since then, one or more magazines about corrosion control have been started in most industrialized countries of the world.

In addition to the present NACE International association, many other scientific engineering, governmental, and trade organizations are active in corrosion control work. Leaders among the scientific and engineering groups in North America are the American Society for Metals ASM), American Society for Testing and Materials (ASTM), American Chemical Society (ASC), and The Electrochemical Society (ECS).

There are many other notable groups and associations dealing with some aspects of corrosion prevention and control in the Americas and in the rest of the world. A simple search of the World Wide Web will reveal the busiest of these groups and associations.

| (previous) | Page 7 of 7 | (next Module) |