Herbert Henry Dow (1866–1930)

The

son of a master mechanic who earned his living by making improvements in small

factories in Connecticut and Ohio, Dow possessed not only his father's inventive

genius but even better business acumen. Born in Belleville in Ontario, Canada,

Dow received his formal training from Case School of Applied Science and graduated

in 1888 with a B.S. degree.

The

son of a master mechanic who earned his living by making improvements in small

factories in Connecticut and Ohio, Dow possessed not only his father's inventive

genius but even better business acumen. Born in Belleville in Ontario, Canada,

Dow received his formal training from Case School of Applied Science and graduated

in 1888 with a B.S. degree.

In a college project at Case School of Applied Science (now Case Western Reserve University), he analyzed samples of brine from the wells around Midland, Michigan, which contained small percentages of bromine in ionic form. At the well site he noticed that brine had come to the surface. The oil men considered the oozing brine a nuisance. One of them asked Dow to taste it. “Bitter, isn’t it,” the driller noted. “It certainly is,” Dow added. “Now why would that brine be so bitter?” the driller asked. “I don’t know,” Dow said, “but I’d like to find out.” He took a sample to his lab, tested it, and found it contained both lithium (which helped explain the bitterness) and bromine. His brine analysis indicated that samples from Canton, Ohio, and Midland, Michigan, were richest in bromine in ionic form.

In those days bromine had just a few uses: in medicines, "bromides," and photographic chemicals. The standard method of extracting bromine was to:

- Evaporate the brine using the leftover wood scraps from the fast-disappearing lumber industry for fuel

- Remove the sodium chloride, which crystallized first

- Add an oxidizing agent to the remaining liquid, which contained bromine ions

- Finally distill the bromine.

As a young man Dow thus entered the rudimentary chemical industry of the 1890s by inventing an entirely new method of extracting bromine from the prehistoric brine trapped underground at Midland, Michigan. His first patent was issued in 1889, and by 1933 he had over 90 patents. He is best known for his work in halogen chemistry, particularly the production of bromine and chlorine. Dow was a public-spirited citizen, serving on boards of public works and education for many years. His favorite saying was, "If we can't do it better than the others, why do it?"

To eliminate the need for the now-costly fuel used in the evaporation and distillation steps, Dow's ingenious plan, executed in 1889 in Canton, Ohio, was to oxidize the brine first with the proper amount of bleaching powder (calcium hydroxide, calcium chloride, and calcium hypochlorite), thus forming bromine, though it was still dissolved in brine. Next the brine was dipped onto burlap sacks, and in a "blowing-out" process a current of air was passed through the brine-soaked sacks to carry off the bromine gas. The bromine-laden air was then brought into contact with iron or an alkali solution, and the bromine was thereby extracted from the air as FeBr2, or alkali bromines.

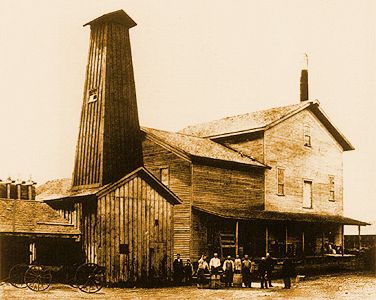

After Dow's first company went bankrupt, he moved to Midland in 1890 and organized the Midland Chemical Company. There he oxidized the brine by electrolysis, using electricity supplied by a second-hand 15-volt generator turned by the old steam engine in the flour mill he had rented in Midland. Midland was a lumbering town with 14 saloons and a doubtful future. There he continued to develop a more efficient process for extracting bromine from the ancient seas under Midland. Just five months later, Dow's ingenuity produced an electrolytic method of bromine extraction from brine, known as the Dow process.

Using a second-hand 15-volt generator that was turned by an old steam engine, Dow was the first to successfully oxidize the bromine by electrolysis in a commercial process. The bromine market seemed to have potential, but Dow never had enough money because nothing ever worked as he expected it to. Electrolysis was new and untested. His brine cells were too small, and the current he passed through the brine was too weak to free all the bromine. When he strengthened the current, he freed all the bromine, but some chlorine seeped in, too. Instead of being frustrated, Dow would later go into the chlorine business as well. After all, people were making money selling chlorine as a disinfectant. Meanwhile, the chlorine and bromine were corroding his equipment and causing breakdowns. He needed better carbon electrodes, a larger generator, and loyal workers.

Dow found himself working 18-hour days and sleeping at the factory. “Crazy Dow” is what the Midland people called him when he rode his dilapidated bike into town to fetch supplies. Laughs, not dollars, were what most townsfolk contributed to his visionary plans. To survive, Dow had to be administrator, laborer, and fundraiser, too. He looked at his resources, envisioned the possible, and moved optimistically to achieve it.

After the bromine process was producing adequately, Dow next wanted to use electrolysis to make sodium hydroxide and chlorine to be turned into bleaching powder, but his first financial backers balked at this diversion of his talents. Dow turned instead to the faculty at Case for capital, forming the Dow Process Company in 1895. After considerable struggle, and yet another business reorganization to form the Dow Chemical Company, he again succeeded with a new process, the first of many successful diversifications and several business reorganizations, first into chlorine chemicals, then into organic chemicals, such as phenol and indigo dye, and finally into magnesium metal.

In 1896, Dow moved both company and family back to Midland, where the company's name officially changed to The Dow Chemical Company in May 1897. From the very beginning, he vowed to make The Dow Chemical Company a research organization, devoted to developing new processes and extracting new products from brine. The company was an immediate success. Just three years later, Dow Chemical Company absorbed Midland Chemical Company. During Dow's lifetime the company obtained its bromine, chlorine, sodium, calcium, and magnesium from the brine of ancient seas under Midland, but Dow, like Fritz Haber, developed experimental processes to mine modern seas. Herbert Dow was serving as president and general manager of the Dow Chemical Company until his death.

Three years after his death in 1930 his company opened its first seawater-processing plant in North Carolina. By World War II, Dow plants on the Gulf Coast were in a position to supply magnesium for firebombs and to make lightweight parts for airplanes.

Connect with us

Contact us today